Reliability engineering Intern

Preventive Maintenance Strategy, Turnaround Planning & UPH Master Data Correction

Top photo. A mega lattice-boom crane lifts the cokers’ upper steel frame during the 2025 Turnaround. The lift opens clear access so the old coke drums can be removed and new drums installed.

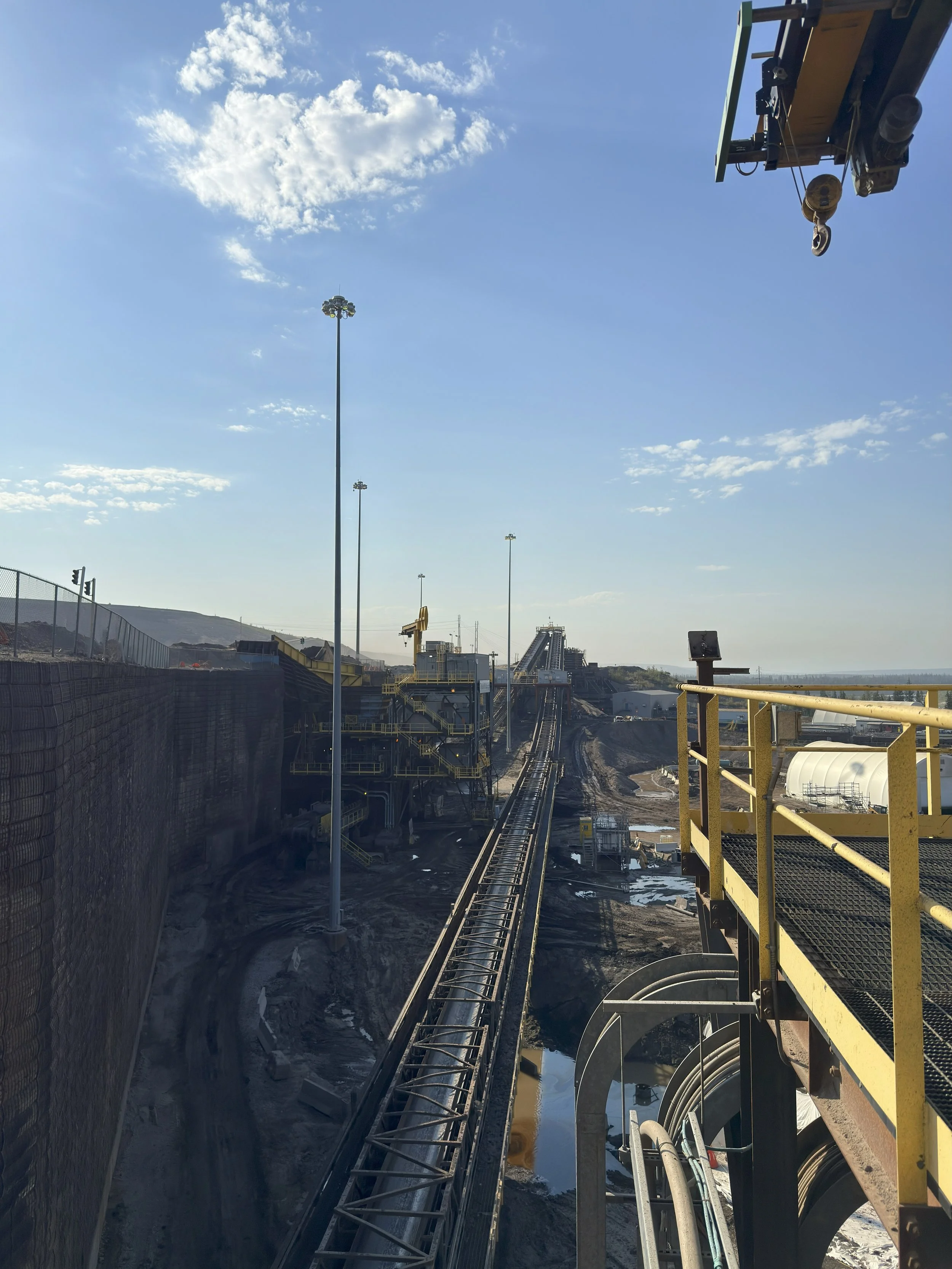

Right photo. Overland trough-belt conveyor carrying raw oil-sand ore from the mining dump trucks, across an MSE-wall transfer corridor, into the primary extraction processing area.

summary of my internship

Across the 8 months at Suncor, I have:

created 126 long-term PM plans created across 66 assets (pumps, heat exchangers, fired heaters, coke drums, fractionators, turbines, motors, etc.)

→ Strategy-controlled timing so future workorders/notifications release on schedule.

prescheduled turnaround planning with multi-year scopes (e.g., tube-bundle replacements and vendor-assisted tasks) to fit outage opportunities and operating windows.

→ This locks high-impact work into planned outages years ahead to maximize runtime, minimize downtime/cost, and reduce execution risks.

validated and corrected the data for 1,114 assets across 5 compressors based on resolving the mismatch between asset-performance (strategy/criticality) and EAM records.

→This ensures all engineers, technicians, managers, planners work with the correct data.

configured 540 maintenance items with clear predecessor/successor relationships

→ Technicians can progress tasks in the right order, reducing manual release errors.

fixed 88 item↔task-list system-condition mismatches and added equipment IDs to 93 items

→ Improves traceability and ensures correct workorder routing across upgrading units.

Tools & Methods across all projects

SAP Enterprise EAM (PM plans/items, task lists, strategy scheduling, IP/IA/IW transactions), GE-APM Asset Performance (strategies/criticality), POWER BI dashboards (QA/QC & audits), Engineering document management (P&IDs/isometrics), Master Data Management (C/U/D intake), Excel.

Technicalities: strategy planning, finish-start with offsets, PRT/checksheet attachment, Sort-Field governance, linked-object migration, DNU protocols, sample testing & PIR.

project #1. Preventive-Maintenance Item & Plan Development

a) Main Problem & Scope

PM coverage was fragmented: many assets on legacy single-cycle plans, inconsistent task lists/long texts, missing/test resource (PRT) links, and weak linkage to outage windows.

Critical classes—pumps, heat exchangers, fired heaters, coke drums, fractionators, turbines, motors—lacked a unified, strategy-controlled approach (intervals, relationships, vendor gates).

b) Objectives & Targets

Build a strategy-controlled PM foundation that automatically “spits out” notifications/WOs at the right horizon.

Create/align plans and items to multi-year strategies (e.g., 5/10-year overhauls, 4-year outage tasks, 6-month oil changes).

Embed task relationships and PRTs/checksheets to reduce release errors and improve auditability.

c) My Actions

Developed 126 long-term PM plans across 66 assets (pumps/exchangers/fired heaters/coke drums/fractionators/turbines/motors).

Added 35 new pump items to codify 10-year vendor overhauls (with NDE such as casing-thickness checks/HVOF options) and 6-month oil-change cycles.

Converted legacy single-cycle content into strategy plans; standardized titles, scope texts, and strategy codes; ensured every plan had a Sort Field.

Attached PRTs and checksheets; cleaned long text (online/offline constraints, references) and made conditions explicit.

Built predecessor/successor relationships for 540 maintenance items, with finish-start links/offsets so manual step progression is enforced at WO release.

Consolidated umbrella PMs for valve/flow/level scopes; merged ignition valves vs. solenoid shutoffs by lifecycle (5/10-year packages) and harmonized nuclear vs. bubbler level-measurement maintenance.

Pre-scheduled near- and long-range scopes (e.g., exchanger tube-bundle cleaning in nearer windows, replacements in longer windows), coordinating vendor presence at outages.

Scheduled safety-critical inspections well ahead of turnarounds (e.g., ~18 months), staggered weekly for load-levelling.

d) Results

Strategy-driven release with correct relationships/PRTs and clean scope texts → fewer mis-calls, fewer task-release errors, and cleaner audits.

Pumps now run on a predictable 10-year overhaul + 6-month oil-change cadence (via 35 items), improving reliability and planning discipline.

540 graphically-linked items enforce the right execution order at release, reducing delays and hand-off ambiguity.

Long-range scopes are pre-positioned against outage windows, improving vendor readiness and minimizing last-minute scope churn.

project #2. Asset-Hierarchy Master-Data Improvement

a) Main Problem & Scope

Functional-location (L2–L6) and equipment mappings were inconsistent (duplicates, mislabels, deletion-flag nodes still referenced by active task lists).

Incomplete Equipment IDs and uneven Sort Field usage degraded reporting, routing, and scheduling.

b) Objectives & Targets

Correct hierarchy from plant level down to equipment/subassemblies; align catalogue/ABC, planner group, plant section, cost center, and Sort Fields.

Reconcile asset-performance (strategy/criticality) and EAM records to a single source of truth.

Stage bulk Create/Update/Delete (C/U/D) changes with linked-object migrations (PMs/notifications/WOs/task lists) before retiring old nodes.

c) My Actions

Assessed 5 compressor families, validating 1,114 pivot/validation entries (first-sheet counts) to standardize FLOC/EQ mapping and Sort Field conventions.

Built a remediation plan for 252 functional locations flagged for deletion but still referenced by active task lists (designed replacement TLs and updates to items/plans).

Maintained a master-data tracker with 88 active change items (worklist + updates).

Fixed 88 item↔task-list system-condition mismatches; added Equipment IDs to 93 items to strengthen traceability and WO routing.

Planned linked-object migrations for PMs, notifications, WOs, task lists to the corrected hierarchy before retirement; prepared C/U/D packages for data-management intake; coordinated sample testing and post-implementation review.

Converted legacy single-cycle plans to strategy-controlled plans; executed DNU (deactivate) protocol safely where applicable (disconnect TLs, remove Sort Field, document call history).

d) Results

Clean hierarchy with 1,114 validated lines across 5 compressor families; 252 deletion-flag nodes remediated so no active TL references are left hanging.

88 mismatches resolved + 93 Equipment IDs added → improved WO routing, asset history, and reporting fidelity.

C/U/D packages and migration plans reduced rework and prevented broken references during retirement of obsolete nodes.

Strategy conversion improved horizon calling and made future scheduling more predictable across units.

Project #3 — Scheduling Control & Turnaround Readiness

a) Main Problem & Scope

Thousands of preventive-maintenance plans were missing Sort Fields, and adding a Sort Field to a plan that was already scheduled could back-activate from its last scheduled date, generating retro-dated work orders and cross-area noise.

Safety-critical trip checks and outage PMs lacked a consistent cadence, safeguards, and verified tag coverage.

b) Objectives & Targets

The goal was to eliminate the missing-Sort-Field exposure and prevent unintended activations and floods of retro work orders.

We aimed to institutionalize standard cancellation/audit templates and add “do-not-release” safeguards where appropriate.

We set out to stand up a repeatable trip-check program covering ~31–33 control/safety tags per heater on a ~4-month cadence and to align outage scopes (e.g., steam & drain assist) on 4-year cycles.

c) My Actions

Reviewed 1,500+ plans and reduced the missing-Sort-Field backlog from 1,756 to 153, with progress tracked in Power BI.

Controlled fallout precisely: I allowed 16 legitimate plan activations, triaged 37 scheduled work orders, removed Sort Fields on 19 mis-assigned plans, and canceled 332 retro-dated work orders.

Standardized the cancellation long-text with date-stamped rationale and applied correct revision codes to preserve a clean audit trail.

Migrated heater trip checks to a program-managed ~4-month cadence, used “do not release immediately” where needed, and verified ~31–33 tags per heater (flows, pressures, valves, ESDs, temperatures).

Built outage-aligned PMs (e.g., steam & drain assist) on 4-year cycles, copied and retuned task lists, set maintenance-package intervals, and ensured relationship logic and PRT links survived conversions.

Pre-scheduled multi-year scopes—near-term cleanings and long-term replacements—and I scheduled safety inspections ~18 months before the TA, staggering them weekly to level the workload.

d) Results

We avoided cross-area activation cascades while the backlog fell from 1,756 to 153, with retro activity contained (332 cancellations) and only 16 legitimate activations proceeding.

We achieved a clean, consistent audit posture through standardized cancellation text and revision coding.

We established a safety program with trip checks every ~4 months and ~31–33 tags per heater, which improved readiness and sharpened alarm-quality discrimination (time-to-change thresholds).

We locked in 4-year outage programs and pre-staged long-range scopes, which produced more predictable execution windows, better vendor coordination, and fewer last-minute changes.

Net Impact

Strategy-driven releases with robust relationships and PRTs reduced release errors and produced cleaner audits.

Hierarchy and data integrity improved through 1,114 validations, 252 DLFL remediations, 88 mismatches fixed, and 93 Equipment IDs added, which strengthened work-order routing and reporting.

Scheduling control (backlog 1,756 → 153, 332 retro WOs canceled), combined with the trip-check and outage programs, delivered higher readiness, safer execution, and more predictable multi-year maintenance.